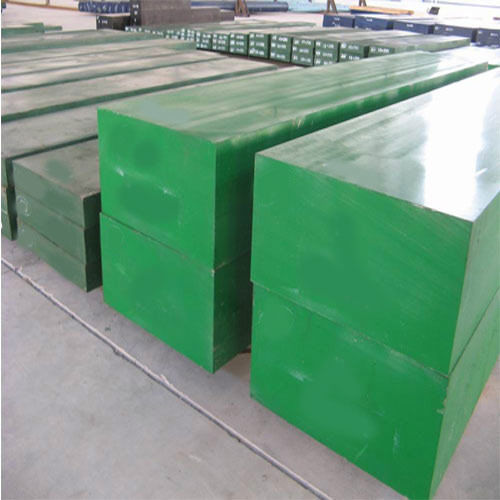

Alloy Steel Block

Product Details:

Alloy Steel Block Price And Quantity

- 200 Kilograms

- 70 INR/Kilograms

Product Description

Product details

| Minimum Order Quantity | 200 Kilogram |

| Material | Alloy Steel |

| Width | 40 to 405 mm |

| Shape | Rectangular |

| Grade | EN-24 |

| Thickness | 15 to 105 mm |

| Application | Automobile Industry |

| Technique | Cold Rolled |

As rolled and Spheroidized Annealed

| Standard | Grade | C | Mn | P | S | Si | Ni | Cr | Mo |

| ASTM A29 | 4340 | 0.38-0.43 | 0.60-0.80 | 0.035 max | 0.040 max | 0.15-0.35 | 1.65-2.00 | 0.70-0.90 | 0.20-0.30 |

| EN 10250 | 36CrNiMo4 / 1.6511 | 0.32-0.40 | 0.50-0.80 | 0.035 max | 0.035 max | 0.40 max | 0.90-1.20 | 0.90-1.2 | 0.15-0.30 |

| BS 970 | EN24 / 817M40 | 0.36-0.44 | 0.45-0.70 | 0.035 max | 0.040 max | 0.10-0.40 | 1.30-1.70 | 1.00-1.40 | 0.20-0.35 |

| JIS G4103 | SNCM 439 / SNCM 8 | 0.36-0.43 | 0.60-0.90 | 0.035 max | 0.030 max | 0.15-0.35 | 1.60-2.00 | 0.60-1.00 | 0.15-0.30 |

Physical Properties:

| Thermal Conductivity at °C | W / (m*K) |

| 20 | 40.5 |

| 350 | 32.5 |

| 700 | 25.5 |

Heat Treatment:

| Soft Annealing °C | 650-700 |

| Cooling | Slowly |

| Hardness HB | max. 280 |

| Stress-relief Annealing °C | 630-650 |

| Cooling | Furnace |

| 1st Pre-Heating °C | up to approx. 400 in an air-circulating furnace |

| 2nd and 3rd | 780 and 1000 |

| Hardening °C | 1190-1230 |

| Quenching | Salt Bath, at least 520°C Oil, Air |

| Tempering °C | at least twice 530-560 |

| Hardness after Temperature HRC | 64-66 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Die Steel Blocks' category

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free