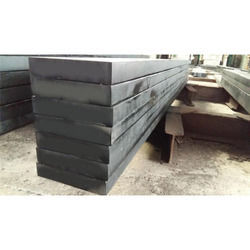

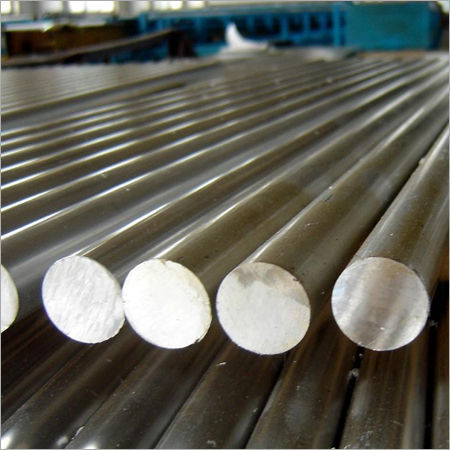

D3 Cold Work Tool Steel

143 INR/Kilograms

Product Details:

- Usage Construction

- Material Stainless Steel

- Surface High Polished

- Thickness 20 to 400 Millimeter (mm)

- Size Standard

- Warranty 1 Year

- Click to view more

X

D3 Cold Work Tool Steel Price And Quantity

- 143 INR/Kilograms

- 200 Kilograms

D3 Cold Work Tool Steel Product Specifications

- Standard

- 20 to 400 Millimeter (mm)

- High Polished

- Construction

- Stainless Steel

- 1 Year

D3 Cold Work Tool Steel Trade Information

- Mumbai Navashiva

- 50-100 Kilograms Per Week

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- All India

Product Description

D3 is a high-carbon, high-chromium, cold work tool steel. It is often used in the manufacture of tools and dies that are subject to high levels of wear and abrasion, and it is known for its excellent hardness, wear resistance, and dimensional stability at elevated temperatures. Here are some key characteristics and applications of D3 cold work tool steel: 1. Chemical Composition: D3 cold work tool steel typically contains around 2.0% to 2.4% carbon, 11% to 13% chromium, and small amounts of other alloying elements such as silicon and manganese. 2. Hardness: D3 steel can be hardened to achieve a high level of hardness, typically in the range of 58-64 HRC (Rockwell Hardness C scale). This makes it suitable for applications where wear resistance is critical. 3. Wear Resistance: D3 steel exhibits excellent wear resistance, which makes it well-suited for cutting, stamping, and forming tools. It can withstand repeated impact and abrasive forces without significant wear. 4. Dimensional Stability: D3 steel has good dimensional stability, meaning that it retains its shape and size even at elevated temperatures, which is important for maintaining precision in tool and die applications. 5. Toughness: While D3 is known for its hardness and wear resistance, it may not be as tough as some other tool steels. It can be more brittle and susceptible to cracking under heavy loads or sudden impacts. 6. Applications: D3 cold work tool steel is commonly used for a variety of applications, including: Blanking and forming dies Punches and stamps Shear blades Thread rolling dies Cold extrusion tools Drawing dies Woodworking tools 7. Heat Treatment: D3 steel can be heat-treated to achieve the desired combination of hardness and toughness. The heat treatment process may involve steps like quenching and tempering to fine-tune the materials properties. Its important to note that there are variations in the composition and heat treatment processes used for D3 steel, and the specific properties can vary accordingly. Proper heat treatment and maintenance are essential to ensure the best performance and longevity of tools and components made from D3 cold work tool steel. When selecting a steel for a particular application, its important to consider factors such as the required hardness, wear resistance, toughness, and the operating conditions to determine if D3 steel is the right choice. D3 Cold Work Tool Steel Specifications: 1. Thermal Conductivity at degree centigrade: 20-700 2. Soft annealing degree centigrade: Approx 670-720 3. Hardening degree centigrade: 940-980FAQs of D3 Cold Work Tool Steel:

Q: What is the surface finish of the D3 Cold Work Tool Steel?

A: The surface finish of the D3 Cold Work Tool Steel is high polished.Q: What material is the D3 Cold Work Tool Steel made of?

A: The D3 Cold Work Tool Steel is made of stainless steel.Q: What is the warranty period for the D3 Cold Work Tool Steel?

A: The D3 Cold Work Tool Steel comes with a 1-year warranty.Q: What is the thickness range of the D3 Cold Work Tool Steel?

A: The thickness of the D3 Cold Work Tool Steel ranges from 20 to 400 millimeters (mm).Q: What is the primary usage of the D3 Cold Work Tool Steel?

A: The D3 Cold Work Tool Steel is primarily used for construction purposes.Q: What size options are available for the D3 Cold Work Tool Steel?

A: The D3 Cold Work Tool Steel is available in standard sizes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Cold Work Steel (IND/USA/EUR)' category

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS