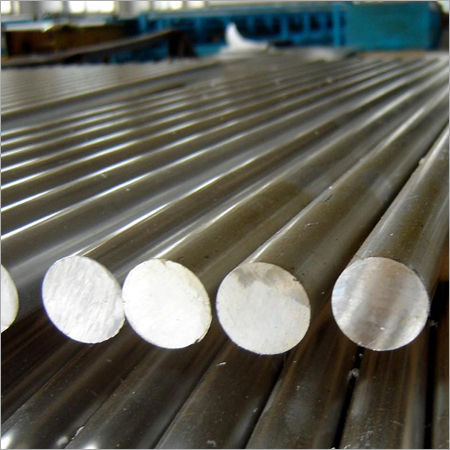

D3 Tool Steel

143 INR/Kilograms

Product Details:

- Usage Construction

- Material Steel Alloys

- Surface High Polished

- Thickness 125 to 1000

- Color Sliver

- Warranty 1 Year

- Click to view more

X

D3 Tool Steel Price And Quantity

- 143 INR/Kilograms

- 200 , , Kilograms

D3 Tool Steel Product Specifications

- Construction

- Steel Alloys

- High Polished

- Sliver

- 1 Year

- 125 to 1000

D3 Tool Steel Trade Information

- 50-100 , , Kilograms Per Week

- 1 Week

Product Description

To meet diversified demands of customers, we have been engaged in manufacturing and supplying exclusive range of D3 Tool Steel to our honorable patrons. It is an air hardening, high carbon, high chromium tool steel. This tool steel displays good abrasion resistance, compressive strength and dimensional stability. It finds applications in blanking & forming dies, forming rolls, press tools, punches, and bushes. Further, D3 Tool Steel has excelled in market by virtue of its great durability and functionality. We assure supply of zero defect products as it is thoroughly tested on parameters of quality and durability prior to shipping.Applications of D3 Tool Steel: 1. Cutting and Shearing Tools: D3 tool steel is often used to manufacture cutting and shearing tools such as slitters, guillotine knives, and circular saw blades. Its high hardness and wear resistance make it suitable for these applications.2. Forming and Stamping Dies: D3 tool steel is used for making forming and stamping dies for processes like blanking, bending, and embossing in the automotive, aerospace, and metalworking industries.3. Cold Work Tooling: D3 is a popular choice for cold work tooling applications, including cold heading dies, cold extrusion dies, and coining dies. It can withstand the stresses and wear associated with these operations.4. Woodworking Tools: In woodworking, D3 tool steel is used to make various cutting tools, including planer knives, chipper knives, and jointer knives. Its wear resistance is beneficial in these applications.5. Thread Rolling Dies: D3 steel is suitable for producing thread rolling dies used in the manufacturing of screws, bolts, and threaded fasteners.6. Plastic Molding Dies: D3 tool steel can be used for making plastic injection and extrusion molding dies. Its hardness and wear resistance help extend the life of these dies.7. Blanking and Piercing Tools: D3 tool steel is employed in the production of blanking and piercing tools used in the automotive and electrical industries.8. Drawing and Deep Drawing Dies: It is used in the manufacture of dies for drawing and deep drawing operations, which shape sheet metal into various forms.9. Forming Rolls: D3 steel can be used for forming rolls used in roll-forming machines that shape metal sheets into specific profiles or shapes.10. Industrial Knives: D3 tool steel is utilized for various industrial knives, including paper cutting knives, film slitter knives, and foil slitter knives.11. Wire Drawing Dies: D3 can be employed for wire drawing dies used in the production of wires of different diameters.12. Billet and Bar Cutters: D3 tool steel is used for billet and bar cutting tools in the metalworking industry, ensuring precise and clean cuts.Frequently Asked Questions: Q. What is D3 tool steel?Ans: D3 tool steel is a high-carbon, high-chromium, oil-hardening tool steel. It is a type of cold work tool steel known for its excellent wear resistance and high hardness.Q. What are the main alloying elements in D3 tool steel?Ans: The primary alloying elements in D3 tool steel are carbon (C), chromium (Cr), and sometimes small amounts of vanadium (V) or molybdenum (Mo).Q. What are the key properties of D3 tool steel?Ans: D3 tool steel exhibits excellent wear resistance, good hardness, and moderate toughness. It is suitable for applications where high wear resistance and hardness are required.Q. What are the common applications of D3 tool steel?Ans: D3 tool steel is used in a variety of applications, including cutting and shearing tools, forming and stamping dies, cold work tooling, woodworking tools, plastic molding dies, thread rolling dies, drawing dies, and more.Q. How is D3 tool steel heat-treated?Ans: D3 tool steel is typically hardened through an oil quenching process. After heating the steel to the appropriate temperature (around 1,020 degree centigrade, it is quenched in oil to achieve the desired hardness and properties.Q. What is the hardness of D3 tool steel after heat treatment?Ans: When properly heat-treated, D3 tool steel typically achieves a hardness in the range of 58-64 HRC (Rockwell Hardness).Q. Is D3 tool steel corrosion-resistant?Ans: D3 tool steel is not highly corrosion-resistant. It is primarily used in applications where wear resistance and hardness are the main requirements, and corrosion resistance is not a primary concern.Q. What are the advantages of using D3 tool steel?Ans: The advantages of using D3 tool steel include its excellent wear resistance, high hardness, and relatively good toughness for a tool steel. It is a cost-effective option for various cold work applications.Q. Are there any limitations to using D3 tool steel?Ans: While D3 offers good wear resistance and hardness, it may not have the same level of toughness as some other tool steels. This can make it more susceptible to chipping or cracking in certain applications. It is important to choose the right tool steel for the specific application requirements.Q. Can D3 tool steel be welded?Ans: D3 tool steel is not readily weldable due to its high carbon and chromium content. Welding can negatively affect the steels properties, and it is generally not recommended. If welding is necessary, consult with a metallurgical expert for guidance.Q. Is D3 tool steel available in various forms and sizes?Ans: Yes, D3 tool steel is available in various forms, including flat bars, sheets, and custom shapes. It can be purchased in different sizes to suit specific tool and die manufacturing needs.Q. What safety precautions should be taken when working with D3 tool steel?Ans: Safety precautions should include using proper personal protective equipment (PPE) when handling and machining D3 tool steel. This may include wearing safety glasses, gloves, and dust masks. Additionally, follow safe machining and heat treatment practices.FAQs of D3 Tool Steel:

Q: What is the primary application of D3 Tool Steel?

A: D3 Tool Steel is primarily used in construction applications.Q: What is the shape of the D3 Tool Steel?

A: D3 Tool Steel is available in the shape of a bar.Q: What type of steel is D3 Tool Steel?

A: D3 Tool Steel is classified as alloy steel.Q: What is the thickness range of the D3 Tool Steel Bars?

A: The thickness of D3 Tool Steel Bars ranges from 125 to 1000.Q: Does D3 Tool Steel come with a warranty?

A: Yes, D3 Tool Steel comes with a 1-year warranty.Q: What is the surface finish of the D3 Tool Steel Bars?

A: D3 Tool Steel Bars feature a high-polished surface.Q: What is the color of D3 Tool Steel?

A: The color of D3 Tool Steel is silver.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Cold Work Steel (IND/USA/EUR)' category

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free