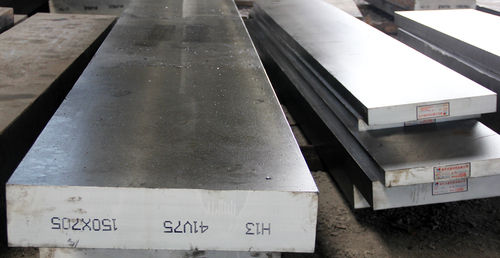

2343 Hot Work Tool Steel

Product Details:

2343 Hot Work Tool Steel Price And Quantity

- 200 Kilograms

- 110.00 - 200.00 INR/Kilograms

2343 Hot Work Tool Steel Trade Information

- 50-100 Kilograms Per Day

- 2 Week

- Contact us for information regarding our sample policy

- All India

Product Description

2343 Hot Work Tool Steel

| Minimum Order Quantity | 200 Kilogram |

| Application | Automobile Industry |

| Soft annealing Degree C | 750 - 800 |

| Hardening Degree C | 1000 -1030 |

| Hardness HB | max 230 |

| Cooling | Furnace |

| Stress relief annealing Degree C | approx 600 - 650 |

We are offering 2343 Hot Work Tool Steel to our clients. It is an all inclusive hot work tool steel with hot rigidity and durability. Good thermal conductivity and invulnerability to hot cracking and can be water cooled to a constrained degree. Utilized for ejector pins, apparatus holders and shrink fit chucks

2343 Hot Work Tool Steel Properties

Hot work tool steel with Chromium 5% has high strength and toughness, best thermal physical phenomenon and in susceptibility to hot cracking. This provides the essential necessities for long tool life in die-casting , Press Forging extrusion processes etc.

2343 Hot Work Tool Steel Physical Properties

| Coefficient of thermal expansion C | 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 |

| 10-6 m/(m*K) | 11.7 | 12.3 | 12.5 | 12.7 | 12.75 | 12.9 | 12.9 |

| Thermal Conductivity C | 20 | 350 | 700 |

| W/(m*K)Annealed | 29.8 | 30.0 | 33.5 |

| W/(m*K)Quenched & Tempered | 26.7 | 27.4 | 30.4 |

Application

Besides applications typical for the area of hot-work steels, this grade is especially used for ejector pins, tool holders, bridge kind tools, liner holders, Forging Dies, Hot work punches, and shrink work chucks.

Heat Treatment

| Soft annealing C | Cooling | Hardness HB |

|---|---|---|

| 750 800 | Furnace | max. 230 |

| Stress-relief annealing C | Cooling |

|---|---|

| approx. 600 650 | Furnace |

| Hardening C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 1000 1030 | Air ,oil or saltbath, 500 550 C | 54 |

| Tempering C | 100 | 200 | 300 | 400 | 500 | 550 | 600 | 650 | 700 |

| HRC | 52 | 52 | 52 | 52 | 54 | 53 | 48 | 37 | 31 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Hot Work Steel (IND/USA/EUR)' category

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free