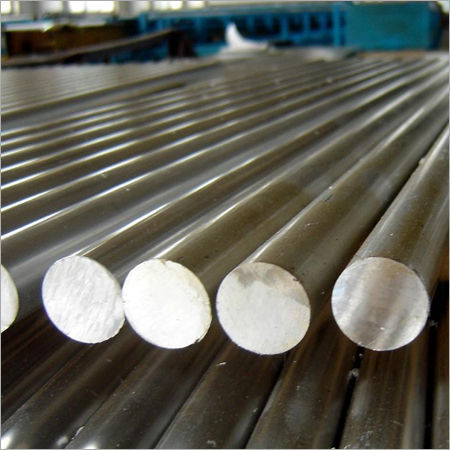

2080 Cold Work Tool Steel

Product Details:

2080 Cold Work Tool Steel Price And Quantity

- 200 Kilograms

- 110.00 - 200.00 INR/Kilograms

- 143 INR/Kilograms

2080 Cold Work Tool Steel Trade Information

- Mumbai Navashiva

- 50-100 Kilograms Per Week

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- All India

Product Description

2080 Cold Work Tool Steel Details:

| Minimum Order Quantity | 200 Kilogram |

| Application | Automobile Industry, Construction |

| Soft annealing Degree C | 810-850 |

| Tempering Degree C after Quenching | 100-600 |

| Quenching | Oil, Air (up to 30 mm thickness) |

| Cooling | Furnace |

| Hardness HB | max 230 |

D3 Steel Having 12 % ledeburitic chromium tool steel with great wears resistance. Basically utilized as cutting tools for sheets up to 4 mm thickness, trimming dies, blanking dies for paper and plastics, shear cutting edges and rotational shear edges for sheet thicknesses up to 2 mm.

Steel PropertiesD3 Steel having properties of High Carbon 2% and High chromium 12 % tool steel with high wear resistance. Its supply condition is normally annealed to easy machining which recommended hardness is 57-58 HRC after making the dies & tools.

2080 Cold Work Tool Steel Physical Properties | Coefficient of thermal expansionat C | 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 |

| 10-6 m/(m*K) | 10.7 | 11.6 | 12.3 | 12.6 | 12.9 | 13.2 | 13.3 |

| Thermal Conductivity at C | 20 | 350 | 700 |

| W/(m*K) | 16.6 | 20.5 | 24.3 |

Application

HCHCR D3 is used in cold Dies & tooling application that required the achievement of high degree of accuracy in hardening & tempering, such as dies drawing, forming cold rolls, powder metal tooling and blanking and trimming dies, blanking dies for paper and plastics, shear blades , cold die punches , Ejector pins etc.

Heat Treatment

| Soft annealing C | Cooling | Hardness HB |

|---|---|---|

| 810 850 | Furnace | max. 245%50 |

| Stress-relief annealing C | Cooling |

|---|---|

| approx. 670-720 | Furnace |

| Hardening C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 940 970 | Oil | 64.5 |

| 950-980 | Air (up to 30 mm thickness) | 64.5 |

| Tempering C after Quenching | 100 | 200 | 300 | 400 | 500 | 600 |

| HRC | 63.5 | 61.5 | 58 | 57.5 | 55 | 47 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Cold Work Steel (IND/USA/EUR)' category

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS