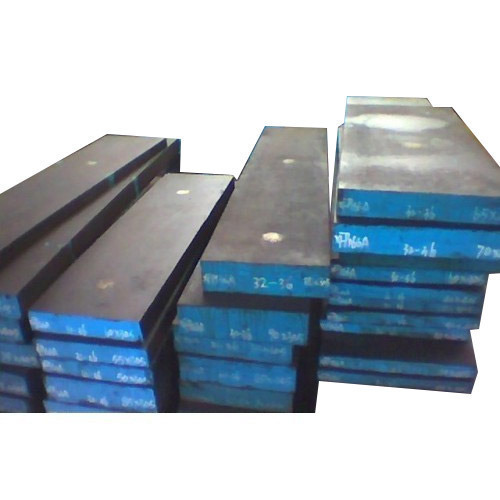

Ni Plastic Mould Steel Block

Product Details:

Ni Plastic Mould Steel Block Price And Quantity

- 200 Kilograms

- 109 INR/Kilograms

Product Description

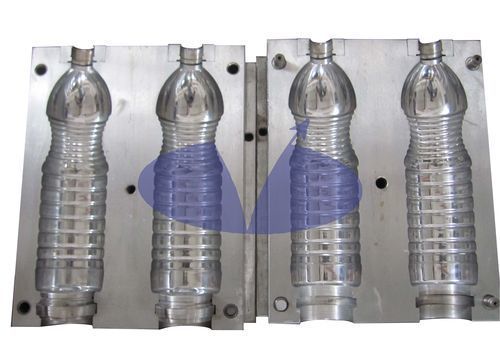

Our NI Plastic Mould Steel Bar provided by us is highly sought after in the industry due to its durability and superb quality. It has great hardening penetration and is used mostly in the manufacture of plastic injection die molds. It has high machinability and is appropriate for medium and large plastic molds. Our NI Plastic Mould Steel Bar is very easy to use and simple to handle. Texturing, fine polishability, acceptable corrosion resistance, and vacuum-degassed steel are all advantages. This bar is very effective as well as economical and safe to use.

Product details

| Minimum Order Quantity | 200 Kilogram |

| Coefficient of thermal expansionat Degree C | 20-700 Deg C |

| Cooling | Furnace |

| Hardening Degree C | 840 - 870 Deg C |

| Hardness after quenching HRC | 51 HRC |

| Hardness HB | Max 235 |

| Quenching | Polymer or Oil |

| Soft annealing Degree C | 710 - 740 Deg C |

| Tempering Degree C after Quenching | 100-700 Deg C |

| Thickness | 125 to 1000 mm |

| Application | Construction |

| Shape | Rectangular |

Chemical Composition - (Typical Analysis in %)

| C | Si | Mn | P | S | Cr | Ni | Mo |

| 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | 0.030max | 0.030max | 1.80-2.10 | 1.90-1.20 | 0.15-0.35 |

Physical Properties:

| Coefficient of Thermal Expansion at °C | 10m / (m*K) |

| 20-100 | 11.2 |

| 20-200 | 12.8 |

| 20-300 | 13.5 |

| 20-400 | 13.7 |

| 20-500 | 14.3 |

| 20-600 | 14.7 |

| 20-700 | 14.9 |

| Thermal Conductivity at °C | W / (m*K) |

| 20 | 35 |

| 350 | 34 |

| 700 | 33 |

Heat Treatment:

| Soft Annealing °C | 710-740 |

| Cooling | Furnace |

| Hardness HB | max. 235 |

| Hardening °C | 840-870 |

| Quenching | Polymer or Oil |

| Hardness after quenching HRC | 51 |

| Tempering°C after quenching | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

| HRC | 51.5 | 50.2 | 48 | 46.2 | 43 | 39 | 29 |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Plastic Mould Steel' category

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS