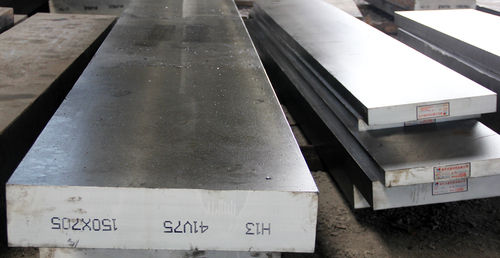

L6 Hot Work Tool Steel

110.00 - 200.00 INR/Kilograms

Product Details:

X

L6 Hot Work Tool Steel Price And Quantity

- 110.00 - 200.00 INR/Kilograms

- 200 Kilograms

L6 Hot Work Tool Steel Trade Information

- 50-100 Kilograms Per Day

- 1 Week

Product Description

L6 Hot Work Tool Steel Details

| Minimum Order Quantity | 200 Kilogram |

| Cooling | Furnace |

| Application | Automobile Industry,Construction |

| Shape | Rounds, Blocks |

| Thermal Conductivity Degree C | 20-700 |

| Soft annealing Degree C | 650-710 |

| Quenching | Oil, Air |

| Hardness after quenching HRC | 55-57 |

| Hardness HB | Max. 240 |

| Hardening Degree C | 840-900 |

Chemical Composition - (Typical Analysis in %)

| STANDARDS | 55NiCrMoV7 | 55NiCrMoV7 | DIN 2714 | AISI L6 | AFNOR | 55NCDVV7 | JIS SKT4 | |

| C | Si | Mn | P | S | Cr | Ni | Mo | V |

| 0.50-0.60 | 0.10-0.40 | 0.65-0.95 | <0.015 | <0.004 | 1.0-1.20 | 1.50-1.80 | 0.45-0 | 0.07-0.12 |

| USA | Europe | Germany | China | Japan | India | R. of Korea | Russia |

| AISI / SAE | En | DIN, WNr | GB | JIS | IS | KS | GOST |

| A681 L6 | 55NiCrMoV7 | 56NiCrMoV7 | 5CrNiMo | SKT4 | T55Ni7Cr4Mo5V1 | STF4 | 4ChMNFS |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hot Work Steel (IND/USA/EUR)' category

|

VENTURA ALLOY AND STEELS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free